Printed electronics to produce reference electrodes

New technologies are required in order to obtain many devices for medicine or the environment at an affordable price, such as printed electronics. Specifically, this study is focused on obtaining, through the inkjet printing technique of a solid-state reference electrode. In addition, a protective membrane to prevent the electrode from becoming obsolete over time is developed.

Today there is a great interest in developing new technologies that allow mass and low-cost production, also known as "rapid prototyping" or "additive manufacturing". Rapid prototyping includes technologies such as stereolithography, 3D printing and laser sintering, among others. All these technologies share the digital design and manufacture from the consecutive addition of layers, in other words, techniques that allow to create any shape or geometric characteristic in a very fast time.

Printed electronics is one of the new technologies that will be important to develop and produce functional electronic devices, with a wide range of applications, electronic designs, processes and materials, in comparison with the conventional electronic and microelectronic manufacturing technology based on silicon.

Among the many areas of interest of these technologies, one of the priorities is the development of low-cost sensors for the medical or environmental area. For example, in these disciplines it is essential to achieve devices that can be very economical or useful to promote a sustainable environmental control and a personalized medicine. Specifically, with inkjet printing technology, a reference electrode in micrometric dimensions has been developed. A reference electrode is the one that has a stable and constant potential over time, and which is essential for taking measurements with any electrochemical sensor.

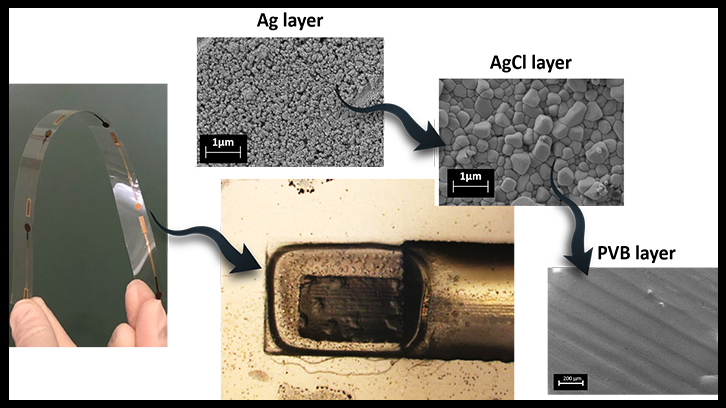

Concretely, it consists of a solid-state reference electrode that brings together all the necessary materials to be able to print with the technique that is laid out layer by layer. Firstly, a silver ink is printed and locally in the area of the electrode a bleach ink is also printed, which will form an Ag/AgCl bilayer, one of the most used interfaces as a reference electrode. Miniaturization faces the problem of the rapid lost of the small reference internal dissolution volume that must be available to these electrodes, since it has a direct impact on their life and stability. Therefore, in the literature there are many strategies to protect the electrode by forming a diffusion barrier that does not increase the stability. The proposal presented in this work is based on the impression of a polymeric membrane that not only protects the external surface of the reference electrode, but also allows ionic contact between the solution and the phase limit that acts as a liquid bonding point. This last layer, formed by a saturated polymer with chlorine ions, forms the protection membrane that makes the reference electrode have high performances compared to other commercially available miniature reference electrodes.

This manufacturing strategy, entirely by ink injection printing, will improve the feasibility of producing low-cost miniature reference electrodes with interest in many electrochemical sensor dependent areas.

This work is the result of the collaboration of several research groups and institutions, basically, of the GAB group of the Barcelona Institute of Microelectronics IMB-CNM (CSIC) that belongs to SU-8 Unit of NANBOSIS of the CIBER in Bioengineering, Biomaterials and Nanomedicine and the GENOCOV group from the Autonomous University of Barcelona, all of them participants in the ENSURE project (ref. RTI2018-099362-B-C21) funded by the MINECO.

Gemma Gabriel Buguña1,2 y Mireia Baeza Labat3

1Institute of Microelectronics of Barcelona, IMB-CNM (CSIC), Universitat Autònoma de Barcelona (UAB).

2 CIBER de Bioengineering, Biomaterials and Nanomedicine (CIBER-BBN).

3 GENOCOV Research Group. Department of Chemistry, Faculty of Science, UAB.

References

Stable Full-Inkjet-Printed Solid-State Ag/AgCl Reference Electrode. Analytical Chemistry. (2019). Moya, A., Pol, R., Martínez-Cuadrado, A., Villa, R., Gabriel, G., Baeza, M. 17;91(24):15539-15546 DOI: 10.1021/acs.analchem.9b03441