From Waste to Resource: Production of Sophorolipids from Second-Generation Substrates

Second-generation raw materials (organic waste and non-food crops) can be recycled to obtain marketable products through the biotechnological process of solid-state fermentation. The GICOM group from UAB confirms its viability in the production of sophorolipids, a valuable bioproduct, and presents promising substrates that can enhance sustainability and efficiency in the industry.

Engineering has been studying the valorization of second-generation raw materials (organic waste and non-food crops) for years, aiming to obtain marketable products. This valorization is carried out using the Solid-State Fermentation (SSF) process. Solid-state fermentation is defined as a heterogeneous biotechnological process with a solid phase, a liquid phase, and a gas phase, where microorganisms grow in the absence or near absence of free water. This technology allows the inoculation of a microorganism onto an organic solid waste to obtain valuable bioproducts, such as biopesticides, biostimulants, or biosurfactants.

As part of the SurfingWaste project (Project PID2020-114087RB-I00), the production of a type of biosurfactant known as sophorolipid is being studied. To produce sophorolipids (SL), a microorganism capable of synthesizing them is required, along with a hydrophobic carbon source (such as oils) and a hydrophilic carbon source (such as sugars). SL can be produced from pure substrates, but to enhance the sustainability of the process, it is advisable to replace these pure substrates with second-generation raw materials. Until now, studies have been conducted using wax removal residues from sunflower oil refining, but alternative fat sources are needed to diversify raw materials.

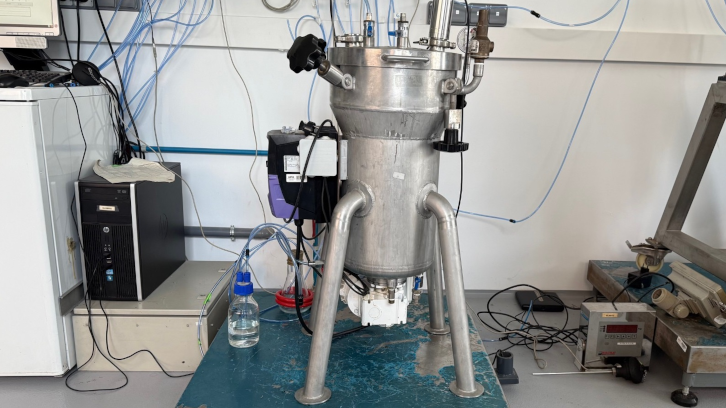

To this end, oilseed filtration residues from corn, sunflower, soybean, and rapeseed have been investigated as new hydrophobic raw materials for SL production through SSF using the yeast Starmerella bombicola. The studies were carried out in laboratory-scale bioreactors of 0.5 L and 22 L. The highest SL production in 0.5 L bioreactors was obtained using corn oil filtration residues (0.743 ± 0.038 g SL g⁻¹ initial fat), a process that was subsequently scaled up to 22 L while maintaining the production level. Although the scaled-up process did not increase SL production, it confirmed the reproducibility of the process at the 0.5 L scale and revealed challenges such as increased temperature during scale-up, which could compromise microorganism viability.

The study demonstrated that second-generation hydrophobic raw materials can be used to produce SL through an SSF process, achieving good production levels. Specifically, the production yields were doubled when using corn or rapeseed oilseed filtration residues, calculated as grams of SL per gram of fat. These results highlight promising substrates that can be utilized in a sustainable production context and Circular Economy initiatives.

Department of Chemical, Biological and Environmental Engineering

Universitat Autònoma de Barcelona

References

Estefanía Eras-Muñoz, Xavier Font, Teresa Gea, (2024) A comparative study of oilseed cakes as hydrophobic feedstocks for sophorolipid production by solid-state fermentation. Industrial Crops and Products, 222: 120059. https://doi.org/10.1016/j.indcrop.2024.120059